Babban Haɗin Wutar Lantarki

Masu haɗa wutar lantarki masu ƙarfi, kuma aka sani da masu haɗa wutar lantarki, nau'in haɗin mota ne. Gabaɗaya suna magana ne ga masu haɗawa da ƙarfin aiki sama da 60V kuma galibi suna da alhakin watsa manyan igiyoyin ruwa.

Ana amfani da manyan haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗe-haɗin-wuta-wuta-wuta-wuta-wuya-wuya-hala-halaye-wuta-wuta-wuta-wuta-wuya-wuya-hala-hala-hala-hala-hala-hala-hala-hala. Suna aiki da wayoyi don jigilar makamashin fakitin baturi ta hanyoyin lantarki daban-daban zuwa sassa daban-daban a cikin tsarin abin hawa, kamar fakitin baturi, masu sarrafa motoci, da masu canza DCDC. manyan kayan wuta kamar masu juyawa da caja.

A halin yanzu, akwai manyan ma'auni guda uku don masu haɗin wutar lantarki, wato LV standard plug-in, USCAR daidaitattun plug-in, da ma'auni na Japan. Daga cikin waɗannan plug-ins guda uku, LV a halin yanzu yana da mafi girman wurare dabam dabam a cikin kasuwannin cikin gida da mafi cikakken ƙa'idodin tsari.

High ƙarfin lantarki connector taro tsarin zane

Tsarin asali na babban mai haɗa wutar lantarki

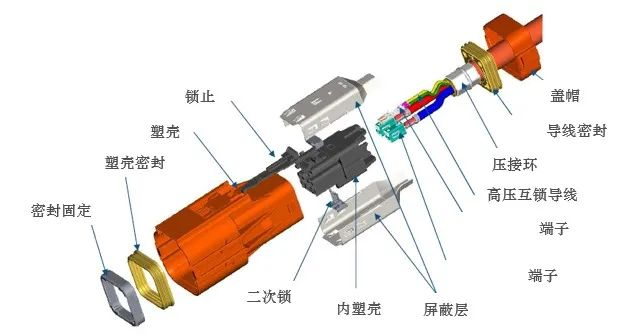

Manyan masu haɗa wutar lantarki galibi sun ƙunshi sifofi huɗu na asali, wato masu tuntuɓar juna, masu insulators, bawo na filastik da na'urorin haɗi.

(1) Lambobi: ainihin sassan da ke kammala haɗin wutar lantarki, wato tashoshi na maza da mata, reed, da dai sauransu;

(2) Insulator: yana goyan bayan lambobin sadarwa kuma yana tabbatar da rufin tsakanin lambobin sadarwa, wato, harsashin filastik na ciki;

(3) Harsashi na filastik: Harsashin mai haɗawa yana tabbatar da daidaitawar mahaɗin kuma yana kare dukkan mai haɗawa, wato, harsashin filastik na waje;

(4) Na'urorin haɗi: ciki har da na'urorin haɗi na tsari da na'urorin shigarwa, watau fil ɗin sakawa, fil ɗin jagora, zoben haɗi, zoben rufewa, levers masu juyawa, tsarin kullewa, da sauransu.

Babban mai haɗa wutar lantarki ya fashe kallo

Rarraba manyan masu haɗa wutar lantarki

Ana iya bambanta masu haɗin wutar lantarki ta hanyoyi da yawa. Ko mai haɗin yana da aikin garkuwa, adadin masu haɗa fil, da sauransu duk ana iya amfani da su don ayyana rabe-raben haɗin.

1.Ko akwai garkuwa ko babu

An raba masu haɗin wutar lantarki zuwa masu haɗin da ba su da garkuwa da masu haɗin garkuwa bisa ga ko suna da ayyukan garkuwa.

Masu haɗin da ba su da garkuwa suna da tsari mai sauƙi, babu aikin garkuwa, kuma ƙananan farashi. Ana amfani da shi a wuraren da ba sa buƙatar garkuwa, kamar kayan lantarki da aka rufe da karafa kamar na'urorin caji, fakitin baturi, da na cikin gida mai sarrafawa.

Misalai na masu haɗawa ba tare da wani Layer na garkuwa ba kuma babu ƙirar kulle-kulle mai ƙarfi

Masu haɗin garkuwa suna da rikitattun sifofi, buƙatun garkuwa, da tsadar tsada. Ya dace da wuraren da ake buƙatar aikin garkuwa, kamar inda waje na na'urorin lantarki ke haɗa su da manyan kayan wutan lantarki.

Mai haɗawa tare da garkuwa da ƙirar ƙirar HVIL Misali

2. Adadin matosai

Ana rarraba masu haɗin wutar lantarki mai ƙarfi gwargwadon adadin tashoshin haɗin gwiwa (PIN). A halin yanzu, waɗanda aka fi amfani da su sune 1P connector, 2P connector da 3P connector.

Mai haɗin 1P yana da tsari mai sauƙi da ƙananan farashi. Ya sadu da kariyar kariya da buƙatun ruwa na tsarin wutar lantarki mai girma, amma tsarin haɗuwa yana da ɗan rikitarwa kuma aikin sake yin aiki ba shi da kyau. Gabaɗaya ana amfani da su a fakitin baturi da injina.

2P da 3P haši suna da hadaddun sifofi da tsada mai tsada. Ya sadu da kariyar kariya da buƙatun ruwa na tsarin wutar lantarki mai girma kuma yana da kyakkyawan kulawa. Gabaɗaya ana amfani da shi don shigarwa da fitarwa na DC, kamar kan fakitin baturi mai ƙarfi, tashoshi masu sarrafawa, tashoshin fitarwa na DC caja, da sauransu.

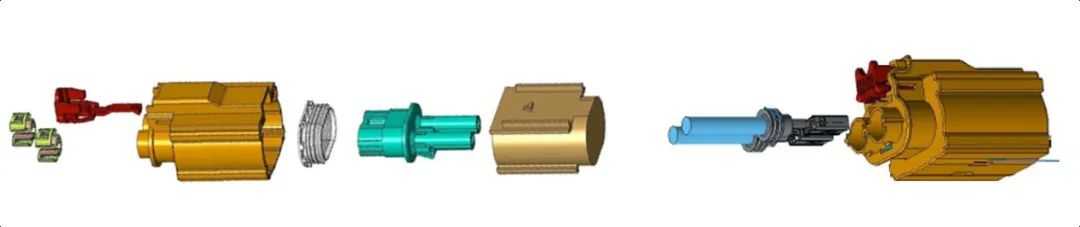

1P/2P/3P babban mai haɗa wutar lantarki misali

Abubuwan buƙatu na gabaɗaya don manyan masu haɗa wutar lantarki

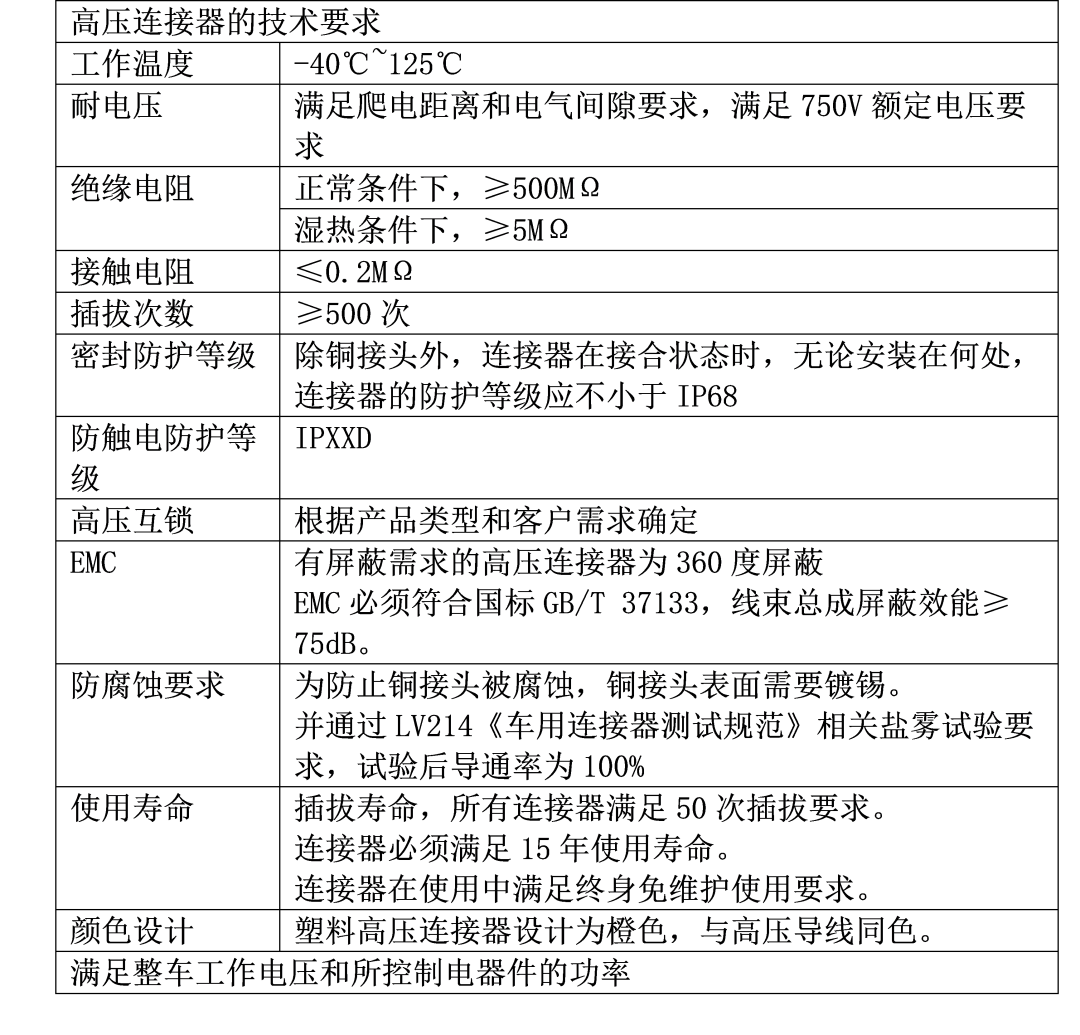

Masu haɗin wutar lantarki ya kamata su bi ka'idodin da SAE J1742 kayyade kuma suna da buƙatun fasaha masu zuwa:

Bukatun fasaha da aka ƙayyade ta SAE J1742

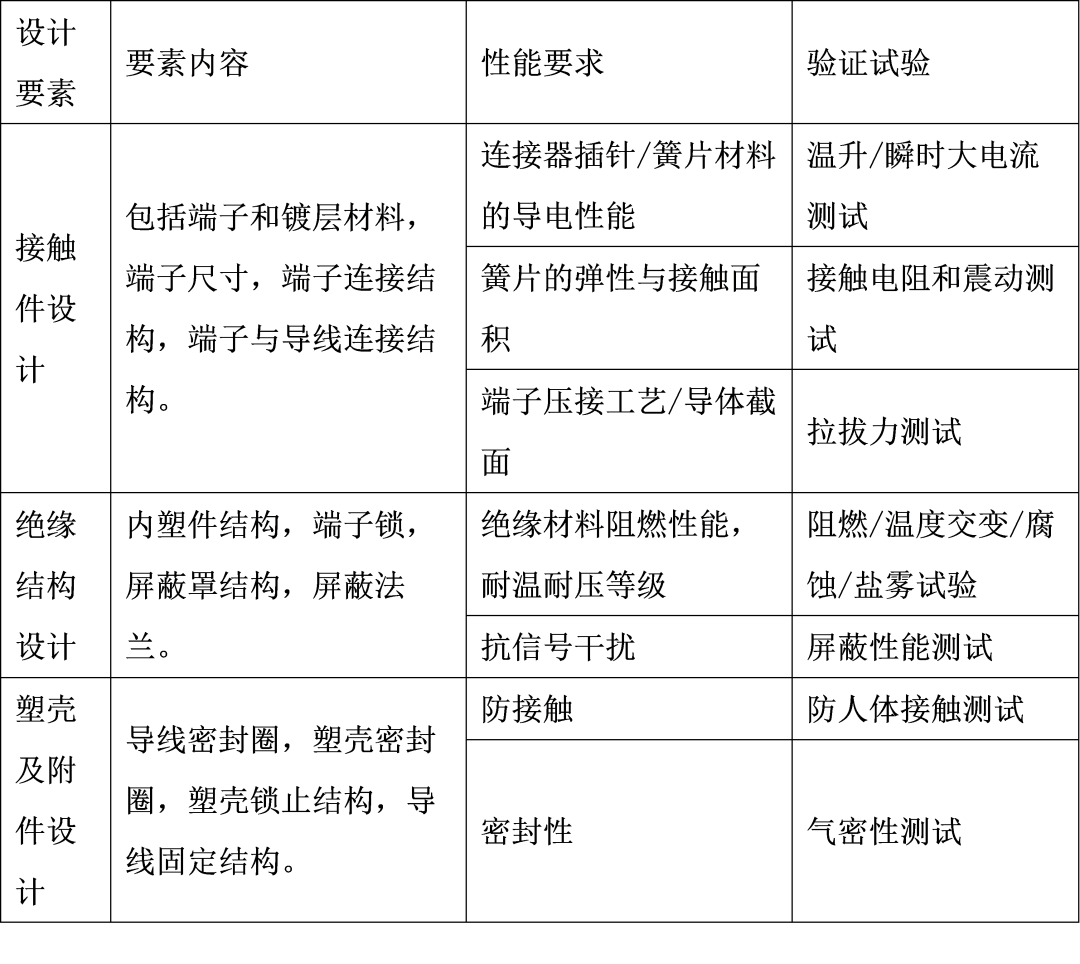

Abubuwan ƙira na manyan masu haɗa wutar lantarki

Abubuwan da ake buƙata don masu haɗin wutar lantarki mai girma a cikin tsarin ƙarfin lantarki sun haɗa da amma ba'a iyakance ga: babban ƙarfin lantarki da babban aiki na yanzu; buƙatar samun damar cimma matakan kariya mafi girma a ƙarƙashin yanayi daban-daban na aiki (kamar yawan zafin jiki, rawar jiki, tasirin haɗari, ƙurar ƙura da ruwa, da dai sauransu); Yi installability; suna da kyakkyawan aikin kariya na lantarki; farashin ya kamata ya zama ƙasa da ƙasa kamar yadda zai yiwu kuma mai dorewa.

Dangane da halayen da ke sama da buƙatun da masu haɗin wutar lantarki ya kamata su kasance da su, a farkon ƙirar ƙira na masu haɗa wutar lantarki, ana buƙatar la'akari da abubuwan ƙira masu zuwa kuma ana aiwatar da ƙirar da aka yi niyya da tabbatar da gwaji.

Lissafin kwatancen abubuwan ƙira, daidaitaccen aiki da gwaje-gwajen tabbatarwa na masu haɗin wuta mai ƙarfi

Binciken gazawa da ma'auni masu dacewa na masu haɗin wutar lantarki

Domin inganta amincin ƙirar haɗin haɗin, ya kamata a fara bincikar yanayin gazawarsa ta yadda za a iya yin aikin ƙira mai dacewa.

Haɗuwa yawanci suna da manyan hanyoyin gazawa guda uku: rashin sadarwa mara kyau, ƙarancin rufewa, da gyare-gyare mara kyau.

(1) Don madaidaicin lamba, ana iya amfani da alamomi kamar juriya mai tsayi, juriya mai tsauri, ƙarfin rabuwar rami ɗaya, wuraren haɗin kai da juriya na jijjiga na abubuwan da aka haɗa don yin hukunci;

(2) Don ƙarancin ƙarancin ƙima, juriya na insulator, ƙimar lalacewar lokaci na insulator, alamun girman insulator, lambobin sadarwa da sauran sassa za a iya gano su don yin hukunci;

(3) Don amincin ƙayyadaddun ƙayyadaddun nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'in juriya),lokacin juriya mai haɗawa da haɗakarwa da haɗin gwiwa,daɗaɗɗen shigar da fitilun, ƙarfin riƙewa a ƙarƙashin yanayin matsalolin muhalli da sauran alamomi na tashar tashar tashar jiragen ruwa da mai haɗawa don yin hukunci.

Bayan nazarin manyan hanyoyin gazawa da siffofin gazawar mai haɗin, za a iya ɗaukar matakan masu zuwa don haɓaka amincin ƙirar haɗin:

(1) Zaɓi mahaɗin da ya dace.

Zaɓin masu haɗawa ya kamata ba kawai la'akari da nau'in da adadin da'irori da aka haɗa ba, amma kuma sauƙaƙe abubuwan da ke cikin kayan aiki. Misali, masu haɗa madauwari ba su da tasiri a yanayin yanayi da na inji fiye da masu haɗin kai rectangular, suna da ƙarancin lalacewa na inji, kuma suna da alaƙa da dogaro da ƙarshen waya, don haka ya kamata a zaɓi masu haɗin madauwari gwargwadon yiwuwa.

(2) Mafi girman adadin lambobin sadarwa a cikin mai haɗawa, ƙananan amincin tsarin. Don haka, idan sarari da nauyi sun ba da izini, gwada zaɓar mai haɗi tare da ƙaramin adadin lambobin sadarwa.

(3) Lokacin zabar mai haɗawa, ya kamata a yi la'akari da yanayin aiki na kayan aiki.

Wannan saboda jimlar nauyin halin yanzu da matsakaicin aiki na mai haɗawa galibi ana ƙididdige su bisa ga zafin da aka ba da izini lokacin aiki a ƙarƙashin yanayin zafi mafi girma na mahallin kewaye. Domin rage yawan zafin aiki na mai haɗawa, ya kamata a yi la'akari da yanayin zafi mai zafi na mai haɗawa. Misali, ana iya amfani da lambobi masu nisa daga tsakiyar mai haɗawa don haɗa wutar lantarki, wanda ya fi dacewa da zubar da zafi.

(4) Mai hana ruwa da kuma hana lalata.

Lokacin da mai haɗawa ke aiki a cikin yanayi tare da iskar gas da ruwa mai lalata, don hana lalata, ya kamata a biya hankali ga yiwuwar shigar da shi a kwance daga gefe yayin shigarwa. Lokacin da yanayi ke buƙatar shigarwa a tsaye, ya kamata a hana ruwa shiga cikin mahaɗin tare da jagororin. Gabaɗaya yi amfani da haɗin haɗin ruwa mai hana ruwa.

Maɓalli masu mahimmanci a cikin ƙirar manyan lambobi masu haɗa wutar lantarki

Fasahar haɗin kai tana bincika yankin lamba da ƙarfin tuntuɓar, gami da haɗin haɗin kai tsakanin tashoshi da wayoyi, da haɗin haɗin kai tsakanin tashoshi.

Amincewar lambobin sadarwa wani muhimmin abu ne wajen tantance amincin tsarin kuma ma wani muhimmin bangare ne na duka manyan kayan aikin wayoyi masu ƙarfi.. Saboda tsananin yanayin aiki na wasu tashoshi, wayoyi da na'urorin haɗi, haɗin kai tsakanin tashoshi da wayoyi, da haɗin kai tsakanin tashoshi da tashoshi suna fuskantar lalacewa iri-iri, kamar lalata, tsufa, da sassautawa saboda girgiza.

Tunda gazawar kayan aikin na'urorin lantarki ta hanyar lalacewa, sako-sako, fadowa, da gazawar lambobin sadarwa suna da sama da kashi 50% na gazawar a cikin dukkan tsarin lantarki, ya kamata a mai da hankali sosai ga amincin ƙirar lambobin sadarwa a cikin amincin ƙirar tsarin lantarki mai ƙarfi na abin hawa.

1. Haɗin haɗi tsakanin tasha da waya

Haɗin kai tsakanin tashoshi da wayoyi yana nufin haɗin kai tsakanin su biyu ta hanyar crimping tsari ko tsarin walda ultrasonic. A halin yanzu, da crimping tsari da ultrasonic waldi tsari da ake amfani da a high-voltage igiyar waya harnesses, kowane da nasa abũbuwan amfãni da rashin amfani.

(1) Tsarin lalata

Ka'idar aiwatar da murkushewa ita ce a yi amfani da karfi na waje don kawai matse wayar madugu ta jiki cikin gurguwar sashin tashar. Tsayin tsayi, faɗin, yanayin ƙetarewa da ja da ƙarfi na crimping na ƙarshe sune ainihin abubuwan da ke cikin ingancin crimping na ƙarshe, waɗanda ke ƙayyade ingancin crimping.

Duk da haka, ya kamata a lura da cewa microstructure na kowane finely sarrafa m surface ne ko da yaushe m da m. Bayan da tashoshi da wayoyi sun lalace, ba lambar sadarwar gabaɗaya ba ce, amma tuntuɓar wasu wuraren da ke warwatse a farfajiyar lamba. , ainihin ma'anar lamba dole ne ya zama ƙarami fiye da ma'anar lamba na ka'idar, wanda kuma shine dalilin da ya sa juriya na tsarin crimping ya yi girma.

Kayan aikin injiniya yana da matukar tasiri ta hanyar crimping, irin su matsa lamba, tsayi mai tsayi, da dai sauransu. Ana buƙatar sarrafa sarrafawa ta hanyoyi kamar tsayin daka da kuma bayanan martaba / bincike na metalographic. Sabili da haka, daidaituwar crimping na crimping tsari shine matsakaici kuma kayan aikin kayan aiki shine tasiri yana da girma kuma dogara shine matsakaici.

Tsarin crimping na crimping na inji ya balaga kuma yana da nau'i mai yawa na aikace-aikace. Tsarin gargajiya ne. Kusan duk manyan masu samar da kayayyaki suna da kayan aikin waya ta amfani da wannan tsari.

Tasha da bayanan bayanan tuntuɓar waya ta amfani da tsari na crimping

(2) Ultrasonic walda tsari

waldi na Ultrasonic yana amfani da igiyoyin girgiza mai ƙarfi don watsawa saman abubuwa biyu da za a yi walda. Ƙarƙashin matsi, saman abubuwan biyu suna shafa juna don samar da haɗuwa tsakanin sassan kwayoyin halitta.

waldi na Ultrasonic yana amfani da janareta na ultrasonic don canza 50/60 Hz halin yanzu zuwa 15, 20, 30 ko 40 kHz makamashin lantarki. Ƙarfin wutar lantarki mai girma da aka canza yana sake komawa zuwa motsi na inji na mita iri ɗaya ta hanyar transducer, sa'an nan kuma motsi na inji yana aikawa zuwa kan walda ta hanyar na'urorin ƙaho waɗanda zasu iya canza girman girman. Shugaban waldi yana watsa makamashin girgizar da aka karɓa zuwa ga haɗin gwiwa na kayan aikin da za a yi waldi. A wannan yanki, ƙarfin girgiza yana jujjuya zuwa makamashin zafi ta hanyar juzu'i, yana narkar da ƙarfe.

Dangane da aikin, tsarin walda na ultrasonic yana da ƙananan juriya na lamba da ƙananan dumama dumama na dogon lokaci; dangane da aminci, abin dogara ne kuma ba sauƙin sassautawa da faɗuwa a ƙarƙashin girgizar dogon lokaci; ana iya amfani dashi don waldawa tsakanin kayan daban-daban; an shafe shi ta hanyar iskar shaka ko shafi na gaba; da waldi ingancin za a iya yi hukunci da sa idanu da dacewa waveforms na crimping tsari.

Ko da yake farashin kayan aiki na ultrasonic waldi tsari ne in mun gwada da high, da karfe sassa da za a welded ba zai iya zama ma lokacin farin ciki (gaba daya ≤5mm), ultrasonic waldi ne mai inji tsari da kuma babu halin yanzu gudana a lokacin dukan waldi tsari, don haka babu wani al'amurran da suka shafi na zafi conduction da resistivity ne nan gaba trends na high-voltage na'ura waya kayan doki waldi.

Tashoshi da masu gudanarwa tare da walƙiya na ultrasonic da sassan haɗin gwiwar su

Ba tare da la'akari da tsarin crimping ko tsarin walda na ultrasonic ba, bayan an haɗa tashar zuwa waya, ƙarfin cirewa dole ne ya dace da daidaitattun buƙatun. Bayan an haɗa waya zuwa mai haɗawa, ƙarfin cirewa bai kamata ya zama ƙasa da ƙaramin ƙarfin cirewa ba.

Lokacin aikawa: Dec-06-2023