1. Kayan aiki

1. Kayan aiki don auna tsayi da faɗi

2. Kayan aiki don buɗe fuka-fuki masu laushi, ko wata hanyar da ta dace da za ta iya buɗe fuka-fukan fuka-fuki na rufin rufi ba tare da lalata tushen mai gudanarwa ba. (Lura: Kuna iya guje wa matakin buɗe fuka-fuki na waya ta filastik ta amfani da hanyar rufewa mara amfani yayin daɗa ainihin wayoyi)

3. Gwajin tilastawa (na'ura mai ɗaukar nauyi)

4. Fitar kai, filawar hanci da/ko madaurin diagonal

2.Samples

Kowane tsayin tsayin da aka gwada yana buƙatar aƙalla samfuran 20 don gwaji (aƙalla tsayin crimping 3 ana buƙatar, kuma ana ba da samfuran tsayi 5 don mafi kyawun zaɓi). Don crimping mai nau'i-nau'i da yawa tare da diamita na waya fiye da ɗaya Layin yana buƙatar ƙara samfurori

3. Matakai

1. A yayin gwajin ƙarfin cirewa, ana buƙatar buɗe fuka-fuki masu murƙushewa (ko ba crimped).

2. Gwajin fitar da karfi yana buƙatar riga-kafin waya (misali, don hana firgita da ba daidai ba kafin gwajin fitar da ƙarfi, ana buƙatar ƙara waya kafin gwajin).

3. Yi amfani da micrometer don yin rikodin tsayin igiyar igiyar waya da faɗin kowane samfurin.

4. Idan reshen ƙuƙƙun rufin bai buɗe ba, yi amfani da mai cirewa don samun wasu kayan aikin da suka dace don buɗe shi don tabbatar da cewa ƙarfin ja yana nuna aikin haɗin haɗin waya kawai.

5. Gano wurin da fikafikan murƙushe ke buɗe don tabbatar da cewa ainihin waya ba ta lalace ba. Kada a yi amfani idan an lalace.

6. Auna da rikodin ƙarfin juzu'i na kowane samfurin a cikin Newtons.

7. Matsayin motsi na axial shine 50 ~ 250mm / min (100mm / min yana bada shawarar).

8. Domin 2-waya layi daya irin ƙarfin lantarki, 3-waya a layi daya irin ƙarfin lantarki ko Multi-waya a layi daya irin ƙarfin lantarki, da daidaici conductors duk suna kasa 1 mm². Ja mafi ƙarancin waya. (Misali, 0.35/0.50 daidaitaccen matsa lamba, ja 0.35 mm² waya)

Domin 2-waya a layi daya irin ƙarfin lantarki, 3-waya layi daya irin ƙarfin lantarki ko Multi-waya a layi daya irin ƙarfin lantarki, kuma a layi daya abun ciki madugu ya fi 1mm², wajibi ne a ja daya tare da mafi karami giciye-section da kuma daya tare da mafi girma giciye-section.

Wasu misalai:

Misali, don matsa lamba na 0.50/1.0, duka wayoyi dole ne a gwada su daban;

Don matsa lamba na 0.5/1.0/2.0 guda uku, ja 0.5mm² da 2.0mm² wayoyi;

Don 0.5/0.5/2.0 uku masu layi daya, ja 0.5mm² da 2.0mm² wayoyi.

Wasu mutane na iya tambaya, menene idan wayoyi masu maki uku duk 0.50mm² ne? Babu wata hanya. Ana ba da shawarar gwada duk wayoyi uku. Bayan haka, ba za mu iya tunanin kowace matsala ba.

Lura: A wannan yanayin, ana buƙatar samfurori 20 don kowane gwajin girman waya. Gwajin kowane ƙima mai ƙarfi yana buƙatar amfani da sabon samfurin.

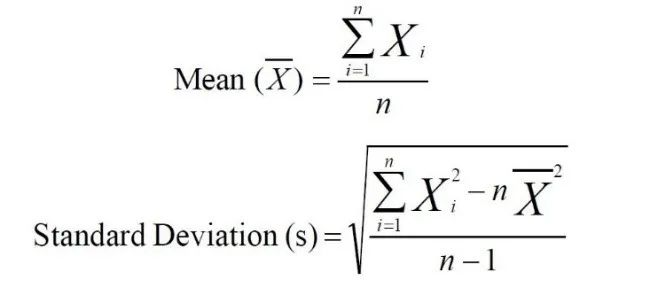

9. Yi amfani da dabarar da ke biyowa don ƙididdige matsakaita da daidaitaccen karkata (amfani da EXCEL ko wasu maƙunsar bayanai masu dacewa don ƙididdige matsakaici da daidaitaccen karkacewar sakamakon tensile da aka samu ta matakin lissafi). Rahoton yana nuna mafi ƙanƙanta, matsakaicin, da matsakaicin ƙima na kowane tsayi mai ɓarna. Ƙimar (`X), madaidaicin karkata (s), kuma yana nufin rage sau 3 daidaitattun sabawa (`X -3s).

Anan, XI = kowace ƙimar ƙarfin ƙarfi, n = adadin samfurori

Formulas A da B - ma'ana da daidaitattun karkatattun ma'aunin ƙarfi

10. Rahoton ya kamata ya rubuta sakamakon duk binciken gani.

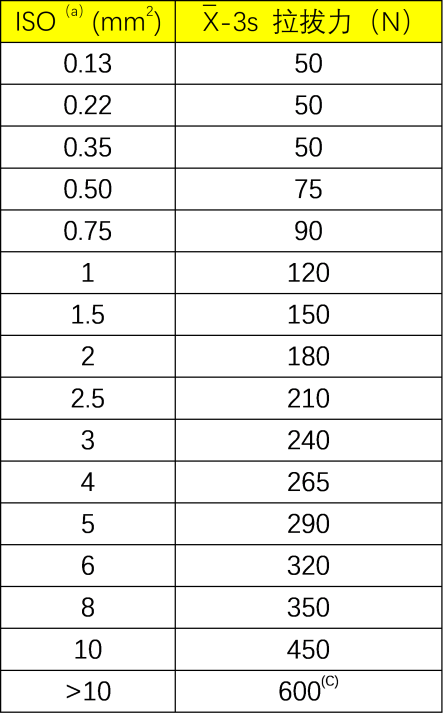

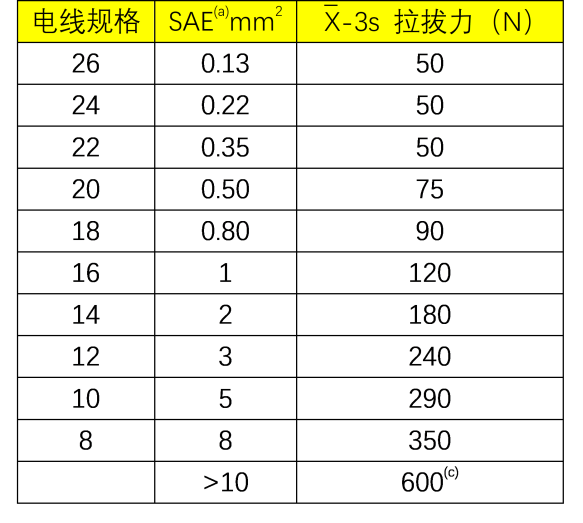

4. Matsayin yarda

Don (`X-3s) da aka lasafta ta amfani da ma'auni A da B, dole ne ya kasance daidai da ko mafi girma fiye da daidaitattun ƙimar ƙarfin ƙarfi a cikin tebur A da B. Don wayoyi tare da ƙimar diamita na waya da ba a jera su a cikin tebur ba, ana iya amfani da hanyar haɗin kai tsaye a cikin Table A da Table B don ƙididdige darajar tashin hankali.

;Lura: Ana amfani da ƙimar ƙarfin ƙarfi azaman alamar ƙima. Lokacin da ƙarfin ja ba zai iya isa ga ma'aunin da aka jera a cikin tebur ba saboda ƙarfin jan waya (ba tare da alaƙa da crimping ba), yana buƙatar a warware shi ta canje-canjen injiniya don inganta waya.

Tebu A da Tebura B - Abubuwan Buƙatun Ƙarfin Jawo (mm da Girman Ma'auni)

Matsayin ma'aunin ISO ya dogara da ISO 19642 Sashe na 4, SAE ya dogara da SAE J1127 da J1128.

Girman waya na 0.13mm2 (26 AWG) ko ƙarami waɗanda ke buƙatar kulawa da kulawa na musamman ba a haɗa su cikin wannan ma'aunin ba.

Don> 10mm2 mafi ƙarancin ƙimar da ake buƙata yana yiwuwa. Babu buƙatar cire shi gaba ɗaya, kuma babu buƙatar ƙididdige ƙimar (`X-3s).

Lokacin aikawa: Nuwamba-28-2023