1.0

Iyakar aikace-aikace da bayani

1.1 Dace da na'ura mai ba da hanya tsakanin hanyoyin sadarwa igiyoyi.

1.2 Lokacin da aka yi amfani da shi a cikin na'urorin wayar hannu na mota, a tashar tashar tashar jiragen ruwa, wayoyi na waya da na'ura mai hana ruwa, ƙayyadaddun ƙayyadaddun bututun zafi mai zafi sun dace da ma'anar mafi ƙanƙanta da matsakaicin girman yankin da aka rufe.

2.0

Amfani da zaɓi

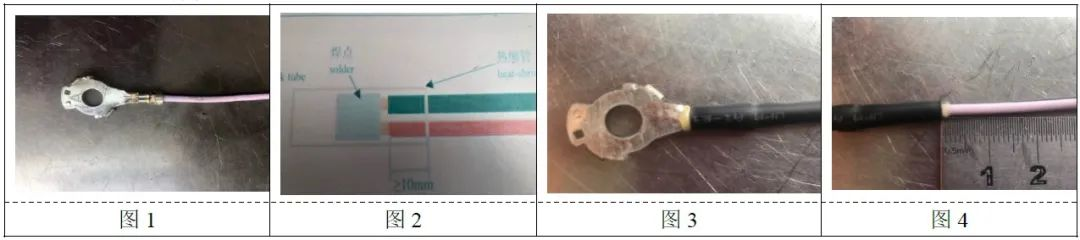

2.1 Tsare-tsare don wayar tarho

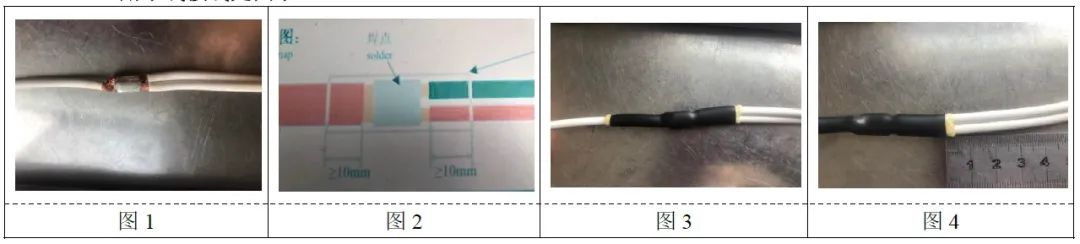

2.2 Zane don haɗin waya

2.3 Umarnin don amfani da zaɓi

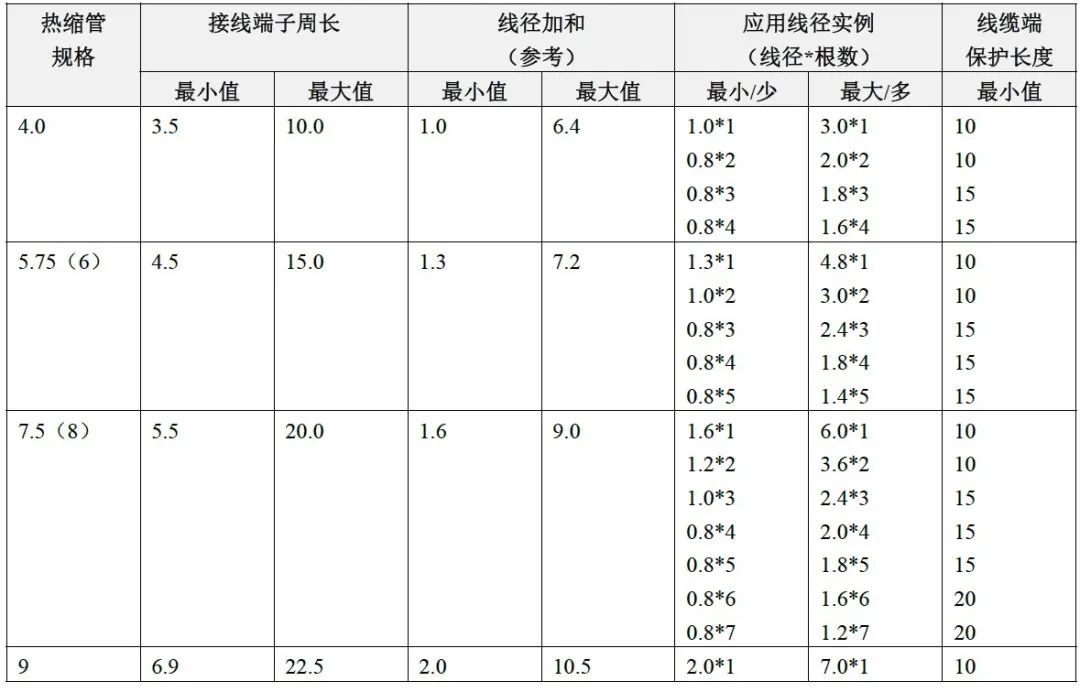

2.3.1Dangane da mafi ƙanƙanta da matsakaicin kewayon kewayon ɓangaren da aka rufe na tashar (bayan crimping), mafi ƙaranci da matsakaicin kewayon diamita na kebul da adadin igiyoyi, zaɓi girman da ya dace na bututun zafi, duba ƙasa don cikakkun bayanai Table 1.

2.3.2Lura cewa saboda yanayi da hanyoyin amfani daban-daban, shawarwarin alaƙar wasiƙa da jeri a cikin Tebu 1 don tunani ne kawai; wajibi ne a ƙayyade wasiƙun da suka dace dangane da ainihin amfani da tabbatarwa, da samar da tarin bayanai.

2.3.3A cikin ma'amala mai ma'ana a cikin Tebu 1, "Misalin Diamita na Waya na Aikace-aikacen" yana ba da mafi ƙaranci ko matsakaicin diamita na waya wanda za'a iya amfani dashi lokacin da akwai wayoyi masu yawa na diamita iri ɗaya. Koyaya, a ainihin aikace-aikacen, akwai wayoyi da yawa tare da diamita na waya daban-daban a ƙarshen ma'amalar kayan aikin waya. A wannan lokacin, zaku iya kwatanta ginshiƙin "jimillar diamita na waya" a cikin Tebura 1. Matsakaicin adadin diamita na waya ya kamata ya kasance cikin kewayon jimillar mafi ƙanƙanta da mafi girman diamita na waya, sannan tabbatar da ko ya dace.

2.3.4Don na'ura mai ba da hanya tsakanin hanyoyin sadarwa ko na'ura mai ba da hanya tsakanin hanyoyin sadarwa, ana buƙatar la'akari da kewayen da ya dace ko kewayon diamita na waya mai dacewa da bututun zafi, kuma yakamata ya iya rufe mafi ƙaranci da matsakaicin girma (dawafi ko diamita na waya) na abin da aka rufe. In ba haka ba, ya kamata a ba da fifiko ga ƙoƙarin yin amfani da bututu masu rage zafi na wasu ƙayyadaddun bayanai don ganin ko zai iya biyan buƙatun amfani; na biyu, ƙirƙira da canza hanyar wayar ta yadda za ta iya biyan buƙatu a lokaci guda; na uku, ƙara fim ko barbashi na roba zuwa ƙarshen waɗanda ba za su iya saduwa da matsakaicin ƙimar ba, ƙaramar Ƙara zafi mai raguwar tubing zuwa ƙarshen ɗaya; a ƙarshe, keɓance samfurin bututu mai zafi mai dacewa ko wani maganin hatimin hatimin ruwa.

2.3.5Ya kamata a ƙayyade tsayin bututun zafi na zafi bisa ga ainihin tsawon kariyar aikace-aikacen. Dangane da diamita na waya, bututun daɗaɗɗen zafi galibi ana amfani da su don haɗa wayoyi ta ƙarshe shine tsayin 25mm ~ 50mm, kuma bututun shrinkable ɗin zafi da ake amfani da shi don wayar tarho shine tsayin 40 ~ 70mm. An ba da shawarar cewa tsawon zafi shrinkable tube kariya na USB rufi ne 10mm ~ 30mm, kuma an zaba bisa ga daban-daban bayani dalla-dalla da kuma girma dabam. Dubi Table 1 a ƙasa don cikakkun bayanai. Tsawon tsayin kariyar, mafi kyawun tasirin rufewar ruwa.

2.3.6Yawancin lokaci, kafin crimping tashoshi ko crimping / walda wayoyi, sanya zafi rage zafi a kan wayoyi da farko, sai dai da waterproof karshen hanyar sadarwa (wato, duk wayoyi suna a daya gefen, kuma babu kanti ko m a daya karshen) Wiring). Bayan crimping, yi amfani da na'ura mai hana zafi, bindigar iska mai zafi, ko wata takamaiman hanyar dumama don yin dumama shrinkage don rage zafin zafi da kuma gyara shi a cikin tsarin kariya.

2.3.7Bayan raguwar zafi, bisa ga ƙira ko buƙatun aiki, an fi son dubawa na gani don tabbatar da ko ingancin aikin yana da kyau. Alal misali, duba gaba ɗaya bayyanar cututtuka irin su ƙumburi, bayyanar da ba daidai ba (watakila ba zafi ba), kariya ta asymmetric (matsayin ya motsa), lalacewar farfajiya, da dai sauransu duba duka ƙarshen ko murfin yana da ƙarfi, ko manne ya cika da rufewa a ƙarshen waya yana da kyau (yawanci ambaliya shine 2 ~ 5mm); ko kariya ta hatimi a tashar yana da kyau, kuma ko manne ya mamaye iyakar da ƙira ke buƙata, in ba haka ba yana iya shafar taron. da dai sauransu.

2.3.8Lokacin da ya cancanta ko buƙata, ana buƙatar samfur don duba hatimin hana ruwa (na'urar dubawa ta musamman).

2.3.9Tunatarwa ta musamman: Tashoshin ƙarfe suna gudanar da zafi da sauri lokacin zafi. Idan aka kwatanta da keɓaɓɓun wayoyi, suna ɗaukar ƙarin zafi (yanayi iri ɗaya da lokacin ɗaukar zafi), gudanar da zafi da sauri (asara zafi), kuma suna cinye zafi mai yawa yayin ayyukan dumama da raguwa. Zafin yana da girman gaske.

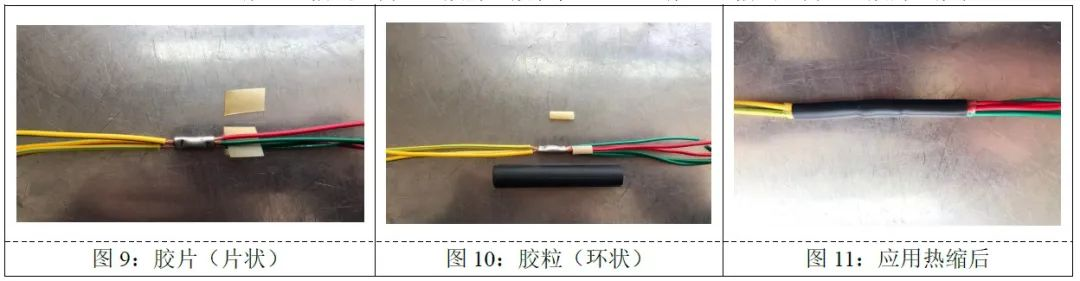

2.3.10Don aikace-aikacen da manyan diamita na waya ko adadi mai yawa na igiyoyi, lokacin da zafi mai narkewa mai zafi na zafi yana raguwa da bututu da kansa bai isa ya cika gibba tsakanin igiyoyi ba, ana bada shawarar shigar da barbashi na roba (siffar zobe) ko fim (siffar takarda) Don ƙara yawan manne tsakanin wayoyi don tabbatar da tasirin rufewar ruwa. Ana ba da shawarar cewa girman bututun zafi mai zafi shine ≥14, diamita na waya yana da girma kuma adadin igiyoyi yana da girma (≥2), kamar yadda aka nuna a cikin Figures 9, 10, da 11. Misali, 18.3 ƙayyadaddun ƙayyadaddun bututu mai ɗaukar zafi, diamita na waya 8.0mm, 2 wayoyi, buƙatar ƙara fim ko barbashi na roba; 5.0mm waya diamita, 3 wayoyi, bukatar ƙara fim ko roba barbashi.

2.4 Teburin zaɓi na masu girma dabam da diamita na waya wanda ya dace da ƙayyadaddun bututun zafi (naúrar: mm)

3.0

Ƙunƙarar zafi da na'ura mai zafi don tubing ɗin zafi don kayan aikin wayoyi na mota

3.1 Nau'in Crawler na'ura mai hana zafi mai ci gaba da aiki

Na kowa sun hada da TE (Tyco Electronics)'s M16B, M17, da M19 jerin zafi rage injuna, Shanghai Rugang Automation's TH801, TH802 jerin zafi rage injuna, da Henan Tianhai da kansa yi zafi rage inji, kamar yadda aka nuna a Figures 12 da 13.

3.2 Injin rage zafi ta hanyar sa

Na kowa sun haɗa da TE (Tyco Electronics)'s RBK-ILS Processor MKIII heat shrink machine, Shanghai Rugang Automation's TH8001-plus digital networked terminal waya zafi inji inji, TH80-OLE jerin online zafi rage inji, da dai sauransu, kamar yadda aka nuna a Hoto 14, 15 da 16.

3.3 Umarni don ayyukan rage zafi

3.3.1Nau'in nau'ikan injunan rage zafi na sama duk kayan aikin rage zafin zafi ne waɗanda ke fitar da wani adadin zafi zuwa wurin aikin taro don ya zama zafi. Bayan bututun rage zafi a kan taron ya kai isasshen zafin jiki, bututun zafi yana raguwa kuma mannen narke mai zafi yana narkewa. Yana taka rawar nannade sosai, rufewa da sakin ruwa.

3.3.2Don zama ƙarin ƙayyadaddun ƙayyadaddun ƙayyadaddun tsarin zafi shine ainihin bututun zafi mai zafi akan taron. Karkashin yanayin dumama na'urar rage zafin zafi, bututun zafin zafi ya kai ga zafin zafi, bututun zafi yana raguwa, kuma man narke mai zafi ya kai yanayin zafin narke. , Manne mai zafi mai zafi yana gudana don cike giɓi kuma yana manne da aikin da aka rufe, don haka yin hatimi mai inganci mai tsabta ko insulating bangaren taro mai kariya.

3.3.3Daban-daban nau'ikan injunan rage zafin zafi suna da damar dumama daban-daban, wato, adadin fitarwar zafi zuwa ma'ajin aiki a kowane lokaci naúrar, ko ingantaccen fitarwar zafi, ya bambanta. Wasu suna da sauri, wasu suna da hankali, lokacin aiki na rage zafi zai bambanta (na'urar rarrafe tana daidaita lokacin dumama ta hanyar sauri), kuma yanayin zafin kayan aiki da ake buƙatar saita zai bambanta.

3.3.4Hatta injunan rage zafi na samfurin iri ɗaya zasu sami ingantaccen fitarwar zafi daban-daban saboda bambance-bambance a cikin ƙimar fitarwa na kayan aikin dumama, shekarun kayan aiki, da sauransu.

3.3.5Saitin yanayin zafi na injunan rage zafin zafi gabaɗaya yana tsakanin 500°C da 600°C, haɗe tare da lokacin dumama da ya dace (na'urar rarrafe tana daidaita lokacin dumama cikin sauri) don aiwatar da ayyukan rage zafin.

3.3.6Duk da haka, saitin zafin jiki na kayan aikin zafi ba ya wakiltar ainihin zafin da aka samu ta wurin haɗuwa da zafi bayan an zafi. A takaice dai, bututun zafin zafi da kayan aikin sa ba sa buƙatar isa ga digiri ɗari da yawa da injin rage zafi ya saita. Gabaɗaya, suna buƙatar isa zuwa hawan zafin jiki na 90 ° C zuwa 150 ° C kafin a iya rage zafi kuma suyi aiki azaman hatimin sakin ruwa.

3.3.7Ya kamata a zaɓi yanayin tsarin da ya dace don ayyukan haɓaka zafi dangane da girman bututu mai zafi, tauri da laushi na kayan abu, ƙarar girma da halayen zafi na abin da aka rufe, ƙarar girma da yanayin zafi na kayan aiki na kayan aiki, da yanayin zafi na yanayi.

3.3.8Yawancin lokaci zaka iya amfani da ma'aunin zafi da sanyio da saka shi a cikin rami ko rami na kayan aikin rage zafi a ƙarƙashin yanayin tsari, kuma ka lura da matsakaicin zafin da ma'aunin zafi da zafi ya kai a ainihin lokacin a matsayin daidaita ƙarfin fitarwar zafi na kayan aikin zafi a wancan lokacin. (Ka lura cewa a ƙarƙashin yanayin yanayin zafi na zafi guda ɗaya, hawan zafin jiki na zafi na ma'aunin zafi da sanyio zai bambanta da zafin zafin jiki na zafin jiki na zafin jiki yana raguwa da aikin aiki saboda bambancin girma da haɓakar zafin jiki bayan dumama, don haka yawan zafin jiki na ma'aunin zafi da sanyio Ana amfani da ma'aunin zafin jiki wanda aka auna kawai azaman ma'auni na daidaitawa don yanayin tsari kuma baya wakiltar yanayin zafin jiki wanda zafi zai rushe taron zai kai)

3.3.9Ana nuna hotuna na ma'aunin zafi da sanyio a cikin Figures 18 da 19. Gabaɗaya, ana buƙatar takamaiman binciken zafin jiki.

Lokacin aikawa: Nuwamba-14-2023