Kamar yadda ake ƙara yin amfani da masu sarrafa aluminum a cikin kayan aikin lantarki na motoci, wannan labarin yana nazari da tsara fasahar haɗin haɗin wutar lantarki na aluminum, da kuma yin nazari da kwatanta ayyukan hanyoyin haɗin kai daban-daban don sauƙaƙe zaɓi na baya na hanyoyin haɗin wutar lantarki na aluminum.

01 Bayani

Tare da haɓaka aikace-aikacen masu gudanar da aluminium a cikin na'urori masu amfani da wutar lantarki na mota, amfani da na'ura na aluminum maimakon na'urorin jan ƙarfe na gargajiya yana karuwa a hankali. Duk da haka, a cikin aikace-aikace na aluminum wayoyi maye gurbin jan karfe wayoyi, electrochemical lalata, high zafin jiki creep, da madugu hadawan abu da iskar shaka matsaloli ne da dole ne a fuskanci da kuma warware a lokacin aikace-aikace tsari. A lokaci guda, aikace-aikacen wayoyi na aluminum masu maye gurbin wayoyi na tagulla dole ne su cika buƙatun wayoyi na tagulla na asali. Kaddarorin lantarki da injina don guje wa lalacewar aiki.

Domin magance matsaloli kamar lalatawar electrochemical, matsanancin zafin jiki, da iskar oxygenation yayin aikace-aikacen wayoyi na aluminium, a halin yanzu akwai hanyoyin haɗin al'ada guda huɗu a cikin masana'antar, wato: walƙiya walƙiya da walƙiyar matsa lamba, walƙiya walƙiya, walƙiya ultrasonic, da waldawar plasma.

Mai zuwa shine nazari da kwatancen aiki na ƙa'idodin haɗin gwiwa da tsarin waɗannan nau'ikan haɗin gwiwa guda huɗu.

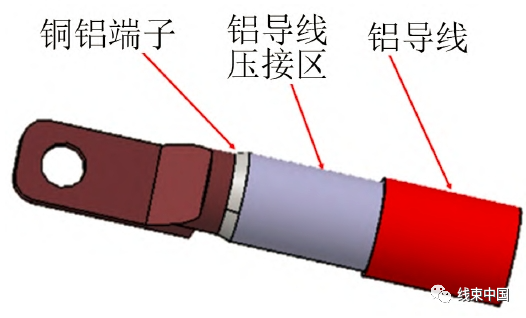

02 Ƙunƙarar walƙiya da walƙiyar matsa lamba

Waldawar juzu'i da haɗa matsi, da farko amfani da sandunan tagulla da sandunan aluminium don waldawar juzu'i, sannan a buga sandunan tagulla don samar da haɗin wutar lantarki. Ana sarrafa sandunan aluminium da injina da sifar su don samar da ƙullun aluminum, kuma ana samar da tashoshi na tagulla da aluminum. Sannan ana shigar da wayar aluminium a cikin ƙarshen ƙarshen tagulla-aluminum na tagulla kuma an lalatar da shi ta hanyar hydraulically ta hanyar kayan aiki na crimping na waya na gargajiya don kammala haɗin gwiwa tsakanin madubin aluminum da tashar tagulla-aluminum, kamar yadda aka nuna a hoto 1.

Idan aka kwatanta da sauran nau'ikan haɗin kai, walƙiya walƙiya da walƙiyar matsa lamba suna samar da yankin miƙa mulki na jan ƙarfe-aluminum gami ta hanyar waldawar igiyoyi na jan ƙarfe da sandunan aluminum. Wurin waldawa ya fi iri ɗaya kuma mai yawa, yadda ya kamata yana guje wa matsalar zafi mai zafi da ke haifar da haɓakar haɓakar haɓakar zafi daban-daban na jan karfe da aluminum. , Bugu da kari, samuwar gawa miƙa mulki yankin kuma yadda ya kamata kauce wa electrochemical lalata lalacewa ta hanyar daban-daban karfe ayyukan tsakanin jan karfe da aluminum. Ana amfani da hatimi na gaba tare da bututun rage zafi don keɓe feshin gishiri da tururin ruwa, wanda kuma yana guje wa faruwar lalatawar electrochemical yadda ya kamata. Ta hanyar crimping hydraulic na aluminum waya da aluminum crimp karshen tagulla-aluminum tashoshi, monofilament tsarin na aluminum conductor da oxide Layer a ciki bango na aluminum crimp karshen an lalace da kuma bawo, sa'an nan sanyi ya ƙare tsakanin guda wayoyi da kuma tsakanin aluminum madugu madugu da kuma ciki karshen bango na crimp bango. Haɗin walda yana haɓaka aikin wutar lantarki na haɗin gwiwa kuma yana ba da ingantaccen aikin injiniya.

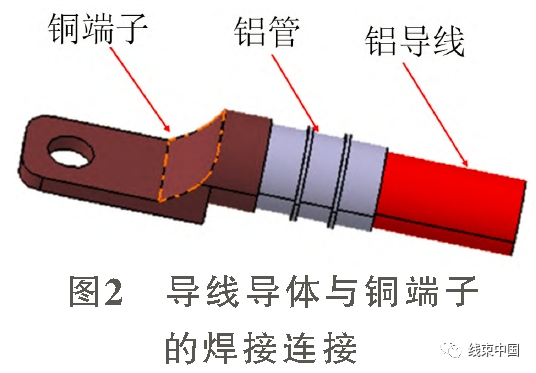

03 Waƙar walda

Waldawar juzu'i yana amfani da bututun aluminium don murƙushewa da siffata madubin aluminium. Bayan yanke ƙarshen fuska, ana yin walda mai jujjuyawa tare da tashar tagulla. Ana gama haɗin walda tsakanin mai kula da waya da tashar tagulla ta hanyar walda mai ƙarfi, kamar yadda aka nuna a hoto na 2.

Weld ɗin juzu'i yana haɗa wayoyi na aluminum. Da farko, an shigar da bututun aluminium a kan mai jagorantar waya ta aluminum ta hanyar crimping. Tsarin monofilament na madugu an yi musu robobi ta hanyar crimping don samar da madaidaicin sashin giciye. Sa'an nan kuma walda giciye-section aka lallashe ta juya don kammala tsari. Shiri na walda saman. Ɗayan ƙarshen tashar tagulla shine tsarin haɗin lantarki, ɗayan ƙarshen kuma shine saman haɗin walda na tashar tagulla. Wuraren haɗin walda na tashar tagulla da saman walda na wayar aluminium ana walda su ana haɗa su ta hanyar walƙiya mai jujjuyawar walda, sannan a yanke walda da siffa don kammala aikin haɗin gwal ɗin walda na aluminum.

Idan aka kwatanta da sauran nau'ikan haɗin gwiwa, walƙiya mai jujjuyawa yana haifar da haɗin kai tsakanin jan ƙarfe da aluminum ta hanyar waldawar gogayya tsakanin tashoshi na jan karfe da wayoyi na aluminium, yadda ya kamata yana rage lalatawar tagulla da aluminum. Yankin miƙa mulki na jan ƙarfe-aluminum gogayya walda an rufe shi tare da manne zafi da tubing a mataki na gaba. Yankin walda ba zai fallasa iska da danshi ba, yana kara rage lalata. Bugu da kari, yankin waldawa shine inda mai sarrafa waya na aluminium ke haɗa kai tsaye zuwa tashar tagulla ta hanyar walda, wanda ke haɓaka ƙarfin fitar da haɗin gwiwa yadda ya kamata kuma yana sauƙaƙe tsarin sarrafawa.

Duk da haka, da disadvantages kuma wanzu a cikin dangane tsakanin aluminum wayoyi da tagulla-aluminum tashoshi a Figure 1. Aikace-aikace na gogayya waldi zuwa waya kayan doki masana'antun na bukatar raba musamman gogayya waldi kayan aiki, wanda yana da matalauta versatility da kuma ƙara da zuba jari a kafaffen kadarorin na waya kayan doki masana'antun. Abu na biyu, a cikin waldawar gogayya A yayin aiwatar da aikin, tsarin monofilament na waya yana yin gogayya kai tsaye tare da tashar tagulla, wanda ke haifar da cavities a cikin yankin haɗin walda. Kasancewar ƙura da sauran ƙazanta za su shafi ingancin walda na ƙarshe, haifar da rashin zaman lafiya a cikin kayan aikin injiniya da lantarki na haɗin walda.

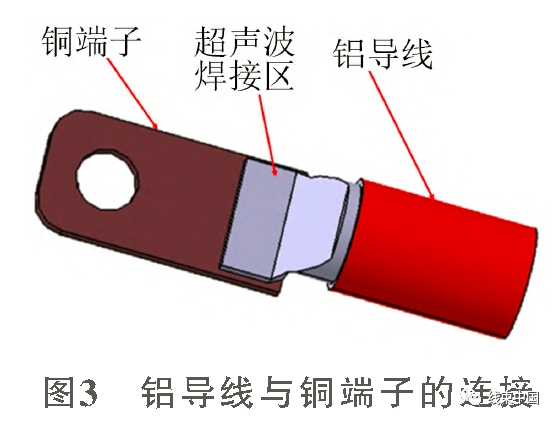

04 Ultrasonic waldi

Ultrasonic waldi na aluminum wayoyi yana amfani da ultrasonic waldi kayan aiki don haɗa aluminum wayoyi da jan karfe tashoshi. Ta hanyar oscillation mai girma na shugaban walda na kayan walda na ultrasonic, an haɗa monofilaments na waya ta aluminum da wayoyi na aluminum da tashoshi na jan karfe don kammala wayar aluminium kuma ana nuna haɗin tashoshi na jan karfe a cikin Hoto na 3.

Haɗin walda na Ultrasonic shine lokacin da wayoyi na aluminium da tashoshi na jan karfe suna rawar jiki a manyan raƙuman ruwa na ultrasonic. Jijjiga da gogayya tsakanin jan karfe da aluminium sun kammala haɗin gwiwa tsakanin jan karfe da aluminum. Domin duka jan karfe da aluminum suna da tsarin lu'u-lu'u na ƙarfe mai siffar siffar fuska, a cikin yanayin juzu'i mai yawa A ƙarƙashin wannan yanayin, an kammala maye gurbin atomic a cikin tsarin kristal na ƙarfe don samar da haɗin haɗin gwal, yadda ya kamata don guje wa faruwar lalatawar electrochemical. A lokaci guda kuma, a lokacin aikin walda na ultrasonic, an cire oxide Layer a saman saman aluminum conductor monofilament, sa'an nan kuma an gama haɗin walda tsakanin monofilaments, wanda ke inganta kayan lantarki da na inji na haɗin.

Idan aka kwatanta da sauran nau'ikan haɗin kai, kayan aikin walda na ultrasonic shine kayan aiki da aka saba amfani da su don masana'antun kayan aikin waya. Ba ya buƙatar sabon ƙayyadadden saka hannun jari. A lokaci guda, tashoshi suna amfani da tashoshi na jan karfe, kuma farashin tashar yana da ƙasa, don haka yana da fa'ida mafi kyawun farashi. Duk da haka, akwai rashin amfani kuma. Idan aka kwatanta da sauran siffofin haɗin gwiwa, ultrasonic waldi yana da rauni inji Properties da matalauta vibration juriya. Sabili da haka, ba a ba da shawarar yin amfani da haɗin walda na ultrasonic ba a cikin manyan wuraren girgizar ƙasa.

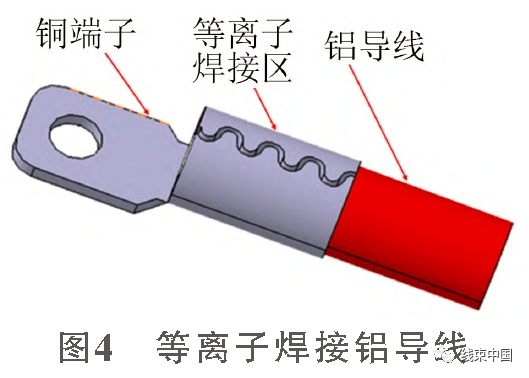

05 Plasma walda

Waldawar Plasma tana amfani da tashoshi na tagulla da wayoyi na aluminium don haɗa haɗin gwiwa, sannan kuma ta hanyar ƙara solder, ana amfani da arc ɗin plasma don kunna wuta da dumama wurin da za a yi walda, narkar da solder, cika wurin waldawa, sannan a kammala haɗin wayar aluminum, kamar yadda aka nuna a hoto na 4.

Waldawar Plasma na aluminum conductors na farko yana amfani da waldawar plasma na tashoshi na jan karfe, kuma an gama ƙullawa da ɗaure masu madubin aluminium ta hanyar crimping. Tashoshin walda na plasma suna samar da tsari mai siffar ganga bayan an datse, sannan kuma wurin waldawar tasha ya cika da solder mai dauke da zinc, kuma karshen shi ne Addara mai dauke da zinc. A karkashin iska mai haske na arc na plasma, mai siyar da ke dauke da zinc yana mai zafi kuma yana narke, sannan ya shiga tazarar waya a cikin yanki ta hanyar aikin capillary don kammala aikin haɗin haɗin tashoshi na tagulla da wayoyi na aluminum.

Plasma welding aluminum wires kammala saurin haɗi tsakanin wayoyi na aluminium da tashoshi na jan karfe ta hanyar crimping, samar da ingantaccen kayan aikin injiniya. A lokaci guda, a lokacin aiwatar da crimping, ta hanyar matsawa rabo daga 70% zuwa 80%, halakar da peeling kashe na oxide Layer na madugu da aka kammala, yadda ya kamata inganta lantarki yi, rage lamba juriya na dangane da maki, da kuma hana dumama da alaka maki. Sa'an nan kuma ƙara solder mai ƙunshe da zinc zuwa ƙarshen wurin da ake murƙushewa, sannan a yi amfani da katako na plasma don haskakawa da dumama wurin walda. Solder ɗin da ke ɗauke da zinc yana zafi kuma yana narkar da shi, kuma mai siyar yana cike gibin da ke cikin wurin da ake murƙushewa ta hanyar aikin capillary, yana samun ruwan feshin gishiri a cikin wurin da ake murƙushewa. Warewar tururi yana guje wa faruwar lalatawar sinadaran lantarki. A lokaci guda kuma, saboda mai siyarwar ya keɓe kuma an ɓoye shi, an kafa wani yanki na canji, wanda ke guje wa abin da ya faru na raɗaɗi na thermal yadda ya kamata kuma yana rage haɗarin haɓaka juriya na haɗin gwiwa a ƙarƙashin girgizar zafi da sanyi. Ta hanyar waldawar plasma na yankin haɗin gwiwa, aikin lantarki na yankin haɗin yana inganta yadda ya kamata, kuma ana ƙara haɓaka kayan aikin injiniya na yankin haɗin gwiwa.

Idan aka kwatanta da sauran nau'ikan haɗin kai, waldawar plasma ta keɓance tashoshi na jan karfe da masu gudanar da aluminium ta hanyar juzu'in walda mai ƙarfi da ƙarfin walda mai ƙarfi, yadda ya kamata ya rage lalata electrochemical na jan karfe da aluminum. Kuma Layer walda da aka ƙarfafa yana nannade ƙarshen fuskar mai sarrafa aluminum ta yadda tashoshin tagulla da ginshiƙi ba za su shiga cikin iska da danshi ba, yana ƙara rage lalata. Bugu da kari, shimfidar walda ta mika mulki da kuma ginshikin walda da aka karfafa tam suna gyara tashoshi na jan karfe da mahaɗin waya na aluminium, yadda ya kamata yana haɓaka ƙarfin fitar da haɗin gwiwa tare da sauƙaƙe tsarin sarrafawa. Duk da haka, akwai rashin amfani kuma. Aikace-aikacen waldawar plasma ga masana'antun kayan aikin waya na buƙatar keɓantaccen kayan aikin walda na plasma, wanda ba shi da ƙarancin ƙarfi kuma yana ƙara saka hannun jari a ƙayyadaddun kadarorin masana'antun kayan aikin waya. Abu na biyu, a cikin tsarin waldawar plasma, ana kammala siyar ta hanyar aikin capillary. Tsarin cike giɓi a cikin yanki na crimping ba shi da iko, yana haifar da ƙarancin walda na ƙarshe a cikin yankin haɗin walda na plasma, yana haifar da manyan ɓatanci a aikin lantarki da injina.

Lokacin aikawa: Fabrairu-19-2024